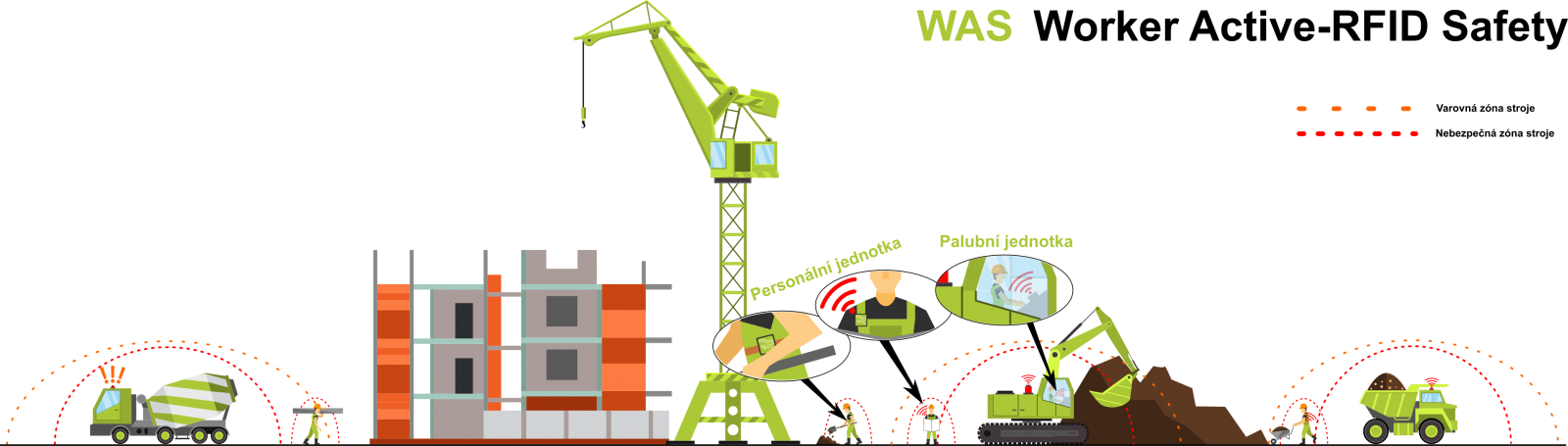

- system designed for additional security of workers in dangerous environments

- detects workers in proximity of dangerous technologies

- audio, light or vibration alarm sets off while entering dangerous zones

- system consists of WAS Tag and WAS Reader devices and the monitoring software

Description: WAS System (Worker Active-RFID Safety) is designed for additional security of workers in dangerous environments. Its function is based on radio identification and localization. The use is primarily designed for construction sites etc., where collision between a worker and a machine or vehicle is a big threat. Worker wears a WAS Tag (personal unit, tag) which transmits radio signals. Surrounding machines are equipped with a WAS Reader (on-board unit, reader), receive the radio signals and evaluate the distance between both devices.

The vicinity of each reader is segmented into the Safe, Warning and Critical perimeters. Size of the perimeters (circular perimeters around the reader antennas) can be individually preset according to the specification of each machine or vehicle.

When a worker enters the Warning or Critical zones, the on-board unit sets off the matching alarm with audio signal and vibrations on the tag, and audio and light signals on the reader. Alarm on a tag can be cancelled only by leaving the dangerous zone, entering the cab of a machine or setting-off alarms for a specific tag. Alarm in a reader can be set-off automatically when the communication between a tag and a reader is interrupted, but in this case the alarm signalization in a tag remains active.

Distance between a tag and a reader is under ideal conditions measured with 0,5m accuracy but the real accuracy is influenced by surrounding environment where shadowing and deflecting of radio signal may occur. Also, when the objects are moving, their speeds and reading intervals must be taken into account.

Considering the principle of the system design, its size is limited to a certain volume of tags and readers located atone spot. In case the number of devices in one area is exceeded, the system gets overloaded which may result in decrease of its reliability or response time.

Entering a machine cab is being evaluated automatically based on distance measuring and radio signal intensity. In such case the on-board reader identifies a tag inside the cab and the alarm signalization is turned off. After leaving the cab the alarm signalization is turned on again with certain delay. The parameter calibration functionality for proper set up of desired parameters is available for each machine and it can be run during the system installation.

In case the worker operating a different machine or vehicle enters the dangerous zone (typically operator of a truck the machine is loading material on), the alarm will not be set off because the second machine must be equipped with a WAS Reader as well.

Due to specific work conditions, operators of specific machines (excavators) are able to prohibit alarm signalization for limited time and limited number of tags. The signalization is activated again after the time limit expires or workers leave the dangerous zone of the machine.

Information about events can be sent, stored and displayed in related information system. Its administrator can remotely manage the system – monitor system functionalities, analyze problematic events, display on-board units and tags and their statuses (battery status, tag -reader distance, alarms, etc.), turn off alarm signalization for specific tags and time periods. Admin can remotely execute complete configuration of units. The software was designed in a client-server architecture.

In case the system needs so be serviced on-spot, the SW Commtest with USB Dongle communication interface can be employed.

WAS System serves as an additional tool for risk prevention, prevention of industrial injuries and material damage. During its operation the correct functionality might be harmfully influenced by specific external conditions (system overload, jam, etc.) Using the WAS System will not divest of observing safety regulations.

Secondary beneficial functionality of the system is a personnel record keeping agenda. Workers equipped with tags can be identified by on-board units with LTE data transfer (if the tags are within reach of radio waves of UWB localization modules) or by means of additional GPS receiver module and long-range radio module transmitting via stationary readers or via LoRaWAN network.

UWB localization reach reader-tag: typically reliable 50m in case the tag is not shielded, max 300m under ideal conditions.

Distance measuring accuracy: 0,5m if a tag is not shielded

Distance measuring interval: cca 1s

Maximum size of the system: 10x WAS Reader, 20x WAS Tag at distance measuring interval 1s.

Maximum number of tags with turned off alarm signalization: 5

Maximum period with turned off alarm signalization: 6 hours

Options of on-board units („car units):

a) option for fixed mounting inside vehicles or machine, respectively mounting in covered space

- box size110x75x25 mm

- cover IP 20

- power supply – connector + cable

b) option for open space mounting – e.g. machine cabs, machines operating in industrial halls or assembly shops, or used directly in external environment

- box size 150x100x45mm

- cover IP 65

- power supply – M12 connector on reader side and free cables or lighter connector on the machine side

WAS Testing Set: